Sintered stone: a type of solid-surface material that is popular in building and design projects, comprising ceramic, porcelain or glass particles which are compressed at very high heat and pressure. Sintered stoned is often used due to the hardness of its surface, and will not scratch or stain on timely basis since it consists low porosity for exterior areas. De-Corpus - De-sintered Stoneworld, and The Best in Safe But Inescapably Bland Design

What are the advantages of sintered stone?

In short, sintered stone is a lot less appealing than traditional building materials which not only makes it ideal material for kitchens or areas near the fireplace. It also provides great thermal stability and has virtually a zero burn rate so it does not ignite or spew harmful toxic gases like natural stone when exposed to naked flame (real test shown in this Prosperities video) It is low/non-porous comparing with the real rock, therefore repellent for water damage as well wicking caused by humidity, which perfect aspects rendering these panels suitable material under high humid environment such bathrooms and swimming pools. That sintered stone is a green product: its carbon footprint for making it new, from the earth instead of recycling unwanted scraps reduces wastage and also allows many unethical mine owners to potentially responsibly manage some land which would not support food crops.

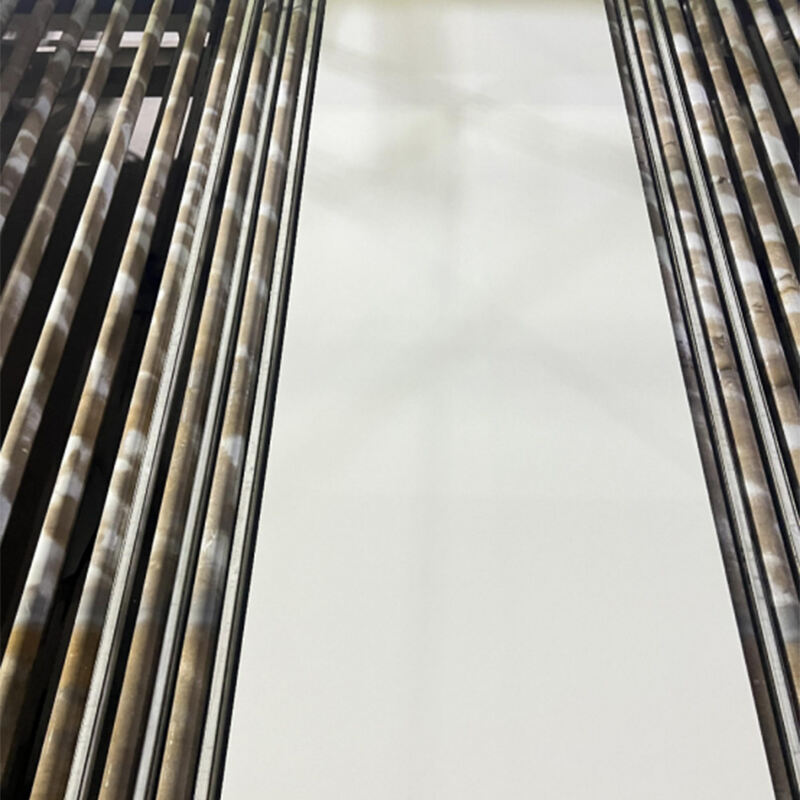

Cutting technologies for sintered stone

This has led to good sintered stone manufacturers continually updating the manufacturing process in order for its final product even better and more sustainable. This may be a minor alteration on the grand scheme of things, but this could greatly reduce their carbon footprint especially if these businesses can adhere to proper recycling protocol and ideally they use up recycled material such as glass or ceramics. Furthermore, they study creating new colors and textures as well patterns loved by the market.

Safety And Strength Of Sintered Stone

Sintered stone is a dependable material that can be used in the making of building and interior designing. Non-toxic, no harmful gases or chemicals and very impact resistant Another great advantage about sintered stone is that it does not create dust when cut or drilled which cuts down on the health risks for both workers and domestic users.

How to Use Sintered Stone

The multiple application possibilities of sintered stone mean it can fill the same role as a kitchen countertop, flooring or wall panels in addition to being used for facade cladding. Edge Sealing - Required to seal the edges of Sintered Stone countertops and blocks, as well before moisture will be dripped inside. For flooring, it can be used with large slabs (tiles) of sintered stone or chopped down into smaller pieces to make a unique design.

Quality of Sintered Stone

The quality of sintered stone can be controlled or chosen during production (process) and in raw materials used, since it is a product that results from the manufacturing process. Reputable manufacturers most of the time do that and this is why their units are going to be highly durable, extremely scratch resistant as well water absorbent. Furthermore, these manufacturers offer comprehensive technical guidance so you can buy the best product for particular requirement of yours.

Sintered Stone: Uses

This is a picture illustrating the use of granite in interior and exterior design (one more source to consider while redecorating your kitchen) - excellent material for making flawless stains that are heat-resistant, but convenient at cleaning. This makes it a great material to be used in bathroom as well as around shower areas due to its low porosity. It can also be used for other applications as well, such a low-cost but visually appealing flooring.

Top 10 Sintered Stone Producers in the World

Neolith: A leading sintered stone manufacturer with a collection of interior and exterior surfaces that are known for their durability, lightweight nature, resistance to scratching along easy cleaning abilities together with its distinctive designs.

An entire range of ultra-thin, sintered stone slabs for vertical wall cladding & horizontal flooring by capexnext corporate an italian manufacturer with lightweight but also a huge aesthetic content #architecture#tableware#furniture.

Porcelainosa - One of the best sintered stone manufacturers that offer colors, finishes and textures where are an amalgamation spec | indoor chequered flooring INFO for Porcelainosa Stylegram 2019

Dekton - Outdoor kitchen and counter top surface, one of the material that resistent to heat.

Lapitec - suitable for interior and exterior applications, this sintered stone slab looks a little like marble.

Fiandre - This is another reliable brand on the market that has sintered stone surfaces and they are already known for their scratch, stain and heat protection properties.

Technistone - Manufactures of sintered stone surfaces for heavy traffic areas: commercial buildings, shopping centres and airports.

Florim - The tiles Mall by Florim+3Where to buy In the typical - down-to-earth yet Italianly-stylish way this company goes about things (yes, that's a word) - there is not much practical information on their website.

Quantra - Manufacturer sintered stone slable with reliable and uniform texture, scratch resistant

SapienStone sintered stone countertops, is a sleek and modern design that not only feels smooth to touch but also resistant-to-water(combined with the joints) & heat.

Conclusion

Sintered stone is not a new material, but Dekton's in particular - jumbo slabs that are 144 inches large by between about 56 and almost to 60 inches wide -- appeals widely for use in homes. They can do this because the best sintered stone manufacturers in world history are doing so, breaking through with game-changing technology that allows them to offer very high-quality products which could be kept beautifully white! Using sintered stone for your next project ensures it will look good and remain strong, making sure that you get a return on the investment in time down the line.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

BN

BN

LO

LO

NE

NE

MY

MY